NEROXIS Inside

NEROXIS builds partnerships to enable you to incorporate its technologies into your products. Different levels of collaboration are possible, from white label distribution to specific R&D developments.

Discover our OEM solutions:

OUR SENSOR COMPONENTS OUR BESPOKE SOLUTIONS

Our sensor components

Neroxis offers gas and pressure sensors, pre-calibrated modules and in-line probes to cover multiple applications in the fields of environmental and industrial control.

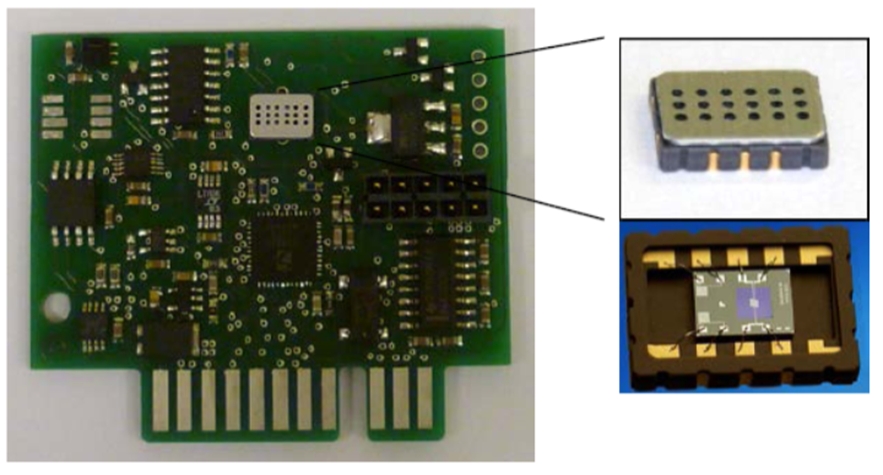

NEROXIS technology is based on the manufacture of microthermal conductivity sensors in micro-electronic MEMS silicon technology. This manufacturing process ensures the reliability and reproducibility of the components at a competitive cost.

• Miniaturisation of the sensors

• Low-energy consumption of sensors and modules suitable for portable instruments

• Provision of pre-calibrated modules compensated for temperature, humidity and pressure that can be directly incorporated into OEM equipment

The principle of operation of a microthermal conductivity sensor (MTCS) for gases relies on the transfer of heat flow from a heated resistor, located on an insulated dielectric membrane, to the cold part of the device. The heat flow depends directly on the conductivity of the gas. The principle is based on the measurement of the signals from the heated part of the device and from the ‘cold’ part at room temperature.

Applications for gas measurement

Monitoring of H2, CH4, CO2, LPG gases for indoor and outdoor air

• Process control in the food industry (e.g. measurement of CO2 in soft drinks)

• Hydrogen sensors for fuel cells and combustion engines

• Measurement of CH4 in biogas plants

• Detection of refrigeration gases (CFC, PFCs, HFCs, etc.)

• Electronic products (e.g., helium control for diving equipment)

• Monitoring of respiratory systems (medical)

• Control of leaks in closed systems operating under inert gas (e.g. strain gauges, quality control of hard disks, etc.)

ADVANTAGES

Low cost and low consumption

Reproducibility and mass production

Calibration/compensation in the plant

MAIN FEATURES

H2, CH4, CO2, He etc selectivity based on a specific detection algorithm

Fast response time <100 ms

‘Plug and Play’ modules

Compatible with portable devices

OUR PRODUCTS

Applications for pressure measurement

• Fixed and portable analytical instruments

• Leak detection and primary vacuum control in closed systems (e.g. kinetic energy storage systems)

• Vacuum equipment used in the semi-conductor industry

• Food industry (vacuum packaging machines)

In general, the small footprint of the Pirani miniature sensors enables their integration into any primary vacuum system requiring their control (e.g. control of sealing, potential corrosion, or inadvertent opening)

ADVANTAGES

High performance (excellent TCR)/repeatability due to the Pirani MEMs utilisation approach, which is possible in corrosive atmospheres (gold version)

Sensor compatible with a standard circuit of the ‘Constant Excess Temperature’ type, allowing its use in all pressure ranges, and the implementation of temperature compensation.

Ease of assembly using the SMD version of the sensors. Reproducibility of the sensors linked to batch production, facilitating their replacement and the calibration of the measuring instruments.

MAIN FEATURES

Vacuum measurement and temperature compensation on the same chip

Optimal sensitivity in the 10-2 to 10+2 mbar range.

Measuring range extending from 10-5 to 10-3 mbar

Gas pressure can be measured in volumes <0.1 cm³

Very low energy consumption (<10mW in ATM, <2mW in HV)

Fast response time <50 ms with high electronic bandwidth

Easy integration into miniaturised systems

Insensitive to the assembly position

High-impact resistance due to their small size

Resistance to corrosive gases used in semi-conductors and other industrial processes

OUR PRODUCTS

Bespoke solutions, R&D outsourcing

NEROXIS produces on-demand developments for the integration of its sensors into customer devices for sales in white labels, as well as providing design and integration studies for complete solutions for end-users. Our teams are available to study your projects. Key accounts that have already put their trust in us: ANDRA, BURKERT, HACH LANGE, VEOLIA etc.